Sunny Slope Greenhouses Page 2

go.ncsu.edu/readext?172559

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲Photos and text by Debbie Roos, Agricultural Extension Agent.

|

Page 2

|

|

This is a 2-3 week old transplant. A good transplant shoot is as wide as it is tall. The trays that the seedlings are produced in have a hole in the bottom that air prunes the tap root which encourages feeder root development.

|

|

Dave transplants seedlings into the larger cells. Note how every other row is filled to give plants room to develop. Dave selects and plants only the best 2,500 seedlings out of the original 3,300 planted. As the transplants grow, light and temperature regimes are adjusted to maximize plant growth and to compensate for weather conditions. |

|

These plants have been growing in the larger cells for about 2-3 weeks and are filling in the extra space.

|

|

These plants are ready for transplanting into the ground. Dave and Jim will select and plant the best 2,200 plants out of these 2,500 transplants.

|

|

Planting is done the week between Christmas and New Year’s. While the transplants have been growing, Jim and Dave have incorporated the compost and lime (if indicated on soil test reports), tilled the beds, laid out and tested drip irrigation lines, covered the beds with white plastic, and cut holes for plants. Black plastic would absorb heat and reduce fuel costs but white plastic reflects light better and light is the biggest factor that they can’t control. Remember that they are growing tomatoes at the time of year when days are the shortest and light level is the lowest. Before the crop is planted they run the heaters for 24 hours and submit air samples to NCSU to make sure that no harmful gases are emitted. They use five 220,000 BTU furnaces, one for each bay. Fuel is the major expense. On a night when it gets down to 32° F, they burn 100 gallons of propane. |

|

It takes about a day per bay to transplant and apply a starter fertilizer solution to each plant to help establish roots. During the growing season, fertilizer needs are determined based on plant tissue analysis. Every 7-10 days, they send a sampling of tomato leaves off for analysis and then apply fertilizer based on the resulting report. Water-soluble fertilizer is injected into the drip irrigation system. You can see part of the trellis system in this photo: notice the bobbins hanging in the top left of the photo – the bobbins are placed on overhead wires, one above each plant, and each contains 25 feet of twine that is lowered down to touch the plant.

|

|

Plant spacing varies throughout the greenhouses but each plant has approximately 4 square feet. Plants in interior bays get about 20% more space because they don’t get as much light. Note that the plants still are just about as wide as they are tall. Around January 1, right after transplanting, Jim and Dave inject millions of beneficial nematodes through the irrigation system to control soil-borne pests such as thrips and fungus gnats. Nematodes are tiny roundworms that live in the soil. Many species feed on plant roots and are considered pests but other species are entomopathogenic, or parasites of insects. These beneficial nematodes, purchased from suppliers that specialize in biological control agents, parasitize insects that spend all or part of their life cycle in the soil. |

|

Speaking of biological control agents…another natural enemy that Jim and Dave purchase and release is the Trichogramma wasp, an egg parasitoid that seeks out eggs of the tomato fruitworm, which damages fruit. These micro-wasps, measuring only about 1/10″ in size, are too fragile to be shipped as adults and so they are shipped ready to hatch inside parasitized eggs glued to a card. Each card contains approximately 120,000 eggs.

|

|

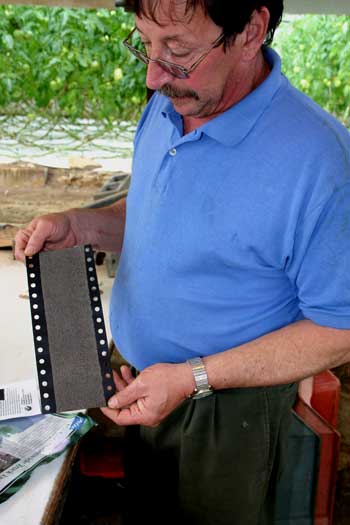

Jim cuts the cards into individual strips to disperse around the greenhouse.

|

|

Close-up of parasitized eggs, which are dark with developing wasps inside. Normal eggs are white.

|

|

Jim attaches the cards to the plants in the areas that he knows are most susceptible to fruitworms – usually near vents and doors and openings.

|

|

The adults emerge from the eggs and search for fruitworm eggs to parasitize in the greenhouse. The wasps are ordered and released monthly in the spring as the temperatures warm up and the fruitworm moths become active and start laying eggs. Sunny Slope employs other biological control agents on an as-needed basis, including predatory lady beetles and lacewing larvae, parasitic Aphidius wasps and predatory Aphidoletes midge larvae for aphid control, parasitic Encarsiawasps for whitefly control, and parasitic nematodes.

|